Ferag’s journey from print powerhouse to intralogistics innovator

Ferag’s journey from a Swiss print industry powerhouse to a global player in intralogistics solutions is a story of engineering excellence, adaptability, and customer-centric values.

Founded in Hinwil, Switzerland, in the 1950s, Ferag initially established itself in the printing sector, specialising in conveying systems and post-printing processing. Its innovative solutions quickly gained worldwide recognition, propelling the company to prominence within the publishing industry.

The technical expertise honed in designing high-speed, precise newspaper and magazine conveyors seamlessly translated to warehouse conveyors, where efficiency, accuracy, and reliability are equally critical.

Much like ensuring the timely delivery of publications to readers, Ferag’s warehouse systems are engineered to move products swiftly and accurately, meeting the demands of modern e-commerce and supply chain operations. This transition was not simply a pivot; it was a natural extension of the company’s commitment to problem-solving

and efficiency.

Today, Ferag stands at the forefront of intralogistics, offering solutions that streamline operations and elevate customer experiences across a variety of industries, including retail, fashion, and e-commerce.

Justin Boyd, Managing Director, Ferag, shares how Ferag’s evolution has always been guided by a core principle: reliability.

“A customer came to us with a machine that was no longer supported, requiring a spare part that was no longer produced,” says Justin. “Upholding our customer-centric ethics, we searched everywhere and found the crucial spare part we needed… in the Ferag museum. The part, still in perfect condition after decades, fit flawlessly, proving Ferag’s commitment to preserving the past while driving innovation for the future.”

Local presence

As Ferag expanded globally, it became clear that the company’s future would require not just technological innovation but also strong localised support networks.

“Our local presence enables us to earn trust and form long-term partnerships, something that’s harder to achieve from afar,” adds Justin. “It also lets us understand and meet local requirements and regulations.”

“Having a presence here allows us to tailor our solutions more effectively, keep spare parts and service teams nearby, and engage more directly in the local industry. This commitment to being local signals to our customers that we’re not just here for the short term, but we’re here to stay.”

Significance of APAC

The Asia-Pacific region has emerged as a hub for growth in logistics and automation, with countries like China, India, and Southeast Asia driving demand for advanced solutions. These economies are experiencing a digital transformation, with e-commerce fuelling an increased need for automated warehousing, sortation, and fulfilment systems. Dynamic market growth requires both speed and flexibility, and Ferag’s systems are built to meet these needs.

“Five years ago, real-time data integration and advanced predictive maintenance weren’t as widely prioritised as they are today,” says Justin Boyd.

“Now, businesses demand more than just automation, they need smart, adaptable systems that provide actionable insights and scale with their operations. Ferag’s solutions are built to meet these demands, combining Swiss engineering precision with innovative technologies.”

Ferag’s systems enable businesses to not only automate processes but also proactively manage challenges, such as fluctuating demand and operational bottlenecks. These capabilities are particularly valuable in APAC, where dynamic market growth requires both speed and flexibility.

Product portfolio

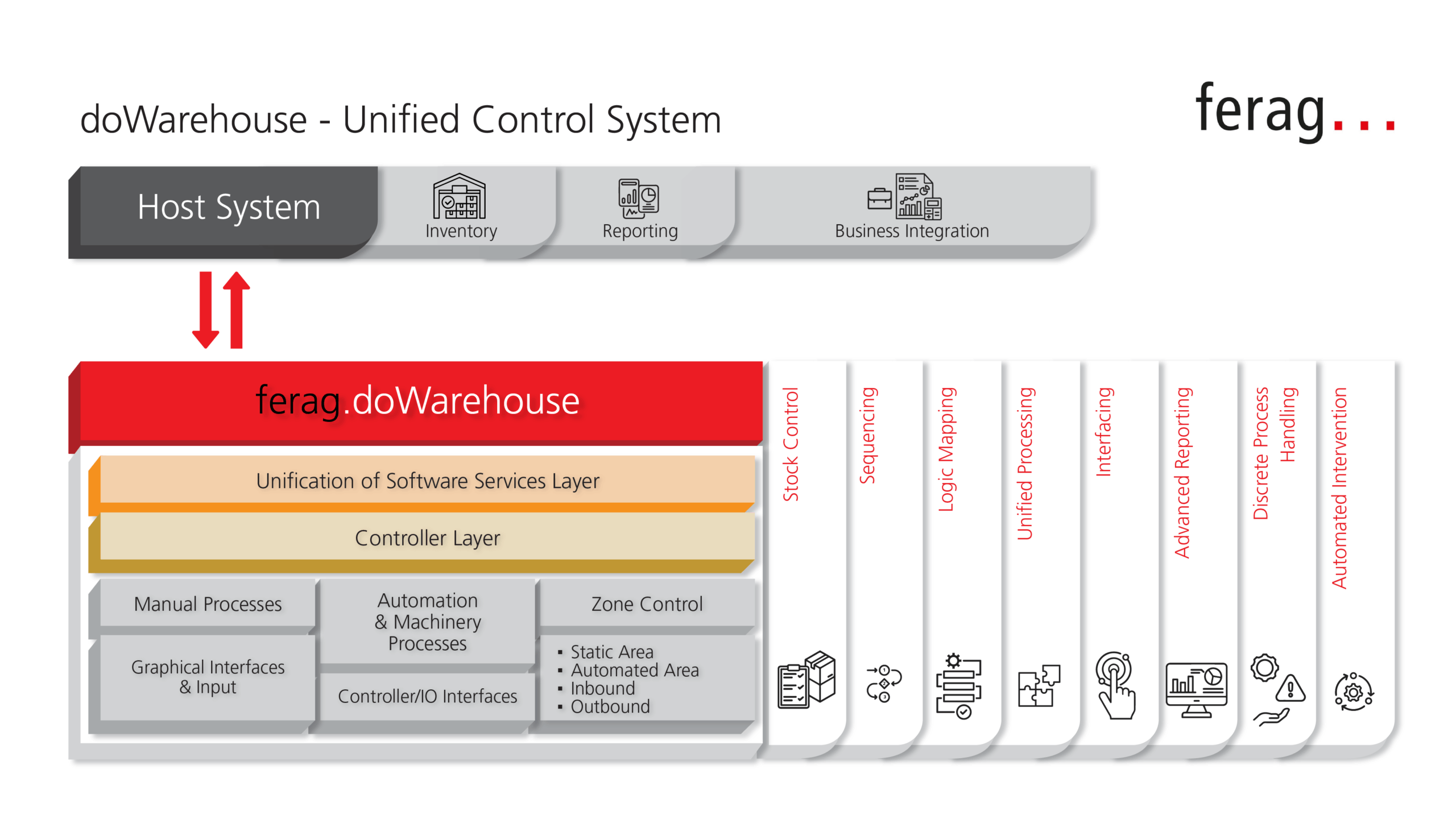

Central to this transformation is Ferag’s doWarehouse solution, which plays a role in integrating the functionality of a Warehouse Management System, a Warehouse Control System and a Warehouse Execution System into one seamless platform.

These features enable companies to optimise processes, reduce costs, and streamline operations in today’s fast-paced logistics environment.

With transparency down to the robotic layer, companies can optimise processes and cut costs in today’s fast-paced logistics environment.

By leveraging data science and machine learning, doWarehouse anticipates system failures, identifies bottlenecks, and optimises demand forecasting. This helps businesses improve operational efficiency and adapt quickly, especially during peak times when operations are under pressure.

doWarehouse offers more than just process automation. It provides actionable insights that drive informed decision-making and continuous improvement. Features like real-time inventory replenishment and precise order tracking enhance productivity while reducing downtime.

“doWarehouse is more than a platform; it’s a bridge between ERP systems and automation. It creates a seamless experience, giving you visibility and control across inbound and outbound processes,” explains Justin.

“Our goal is to make human-machine interaction as intuitive and effective as possible. We believe operational technology should empower users, and that’s what excites us –that’s our passion.”

Another innovation in Ferag’s intralogistics arsenal is Skyfall, a pouch-handling system that seamlessly combines sorting, buffering, and picking functions in one platform. Think of it as a dry cleaner’s conveyor belt, but engineered for industrial precision and scalability. Skyfall goes beyond traditional conveyors, acting as an all-in-one solution that eliminates the need for multiple separate systems, thereby significantly reducing costs and complexity.

What sets Skyfall apart is its energy efficiency. By leveraging gravity and low rolling friction instead of motors, the system minimises energy consumption and maintenance requirements.

“This design not only reduces operational costs but also ensures long-term reliability, making it an ideal solution for dynamic industries,” says Michael Gruber, Director, Customer Service & Support, Ferag.

In addition, Skyfall can handle a range of products, from cosmetics and apparel to electronics and even dangerous goods, making it versatile for a broad array of industries.

“For instance, if a customer needs their products delivered in a specific sequence for easier store restocking, Skyfall can ensure the correct store sequence when loading the truck. This means the goods are unloaded at the store in the correct sequence to be placed on the floor, saving time and storage in the back of the store. This helps optimise the entire supply chain, from the warehouse to the shop floor,” says Michael.

Complementing Skyfall’s capabilities is Denisort, Ferag’s tilt-tray sorting system designed for high-speed, high-accuracy performance. With a unique 3D architecture, Denisort maximises floor space while maintaining exceptional throughput. Its dynamic dual-tray configuration enhances sorting capabilities, making it ideal for high-throughput environments. Denisort is designed for industries like printing, where high-speed, error-free sorting is critical.

“For instance, in the newspaper industry, where thousands of copies must be sorted and delivered within hours, Denisort’s reliability and long lifespan are invaluable,” says Michael. “The system’s low maintenance needs make it an attractive choice for companies looking for long-term, trouble-free operation.”

Digital innovation

Ferag is at the forefront of integrating digital technologies into its material-handling solutions, empowering businesses with tools that drive operational efficiency and resilience. At the core of this effort is advanced data analytics, which optimises system performance by delivering actionable insights into operations, forecasting, and identifying potential issues before they escalate.

“Our AI-driven systems enable prescriptive maintenance by learning from past incidents, allowing us to proactively adjust material flows and tune systems to prevent issues before they arise,” explains Michael.

With its focus on continuous innovation and R&D, Ferag ensures that its products are not just meeting the current needs of industries but are future-proof, helping businesses stay ahead in an increasingly digital and automated world.

“Scenario modelling is a game-changer for our customers,” adds Justin Boyd.

“It lets them simulate different operational conditions to optimise layouts, predict bottlenecks, and make real-time decisions – all without disrupting operations. It’s like a sandbox for training, helping managers prepare for real challenges,” adds Justin.

Among the many roles played by digital technologies, safety stands out as a key focus.

“Safety technology, like wearables, ensures workers stay out of hazardous zones by sending real-time alerts,” explains Justin.

“The goal is simple – keep them safe and ensure they go home in better condition than they arrived.”

Innovative service tools and tailored approach

Ferag’s service offering goes beyond the conventional OEM support, setting itself apart through a combination of agility, innovation, and an understanding of customer needs.

While the baseline service offering across companies is similar, Ferag stands out by leveraging its software expertise to implement predictive and prescriptive maintenance – tools that not only identify potential issues before they arise but also optimise system performance in real time.

“With a young and agile team, Ferag can quickly adapt and implement solutions, exemplified by the rapid deployment of its system monitoring tool toMonitor, which was developed and implemented in just one week – something that would have taken years in larger organisations,” says Michael.

As the industry faces a shortage of qualified personnel, Ferag is tapping into the power of remote diagnostics and data analytics to address this gap. These tools help identify potential failures, reduce downtime, and streamline maintenance, benefiting both customers and the environment by reducing the need for spare parts and lowering costs.

“We also customise our support packages for diverse APAC markets, listening closely to customers’ pain points and tailoring solutions to fit their unique logistical challenges,” explains Michael.

Vision for the future

Looking ahead, Ferag aims to be a leading force in the intralogistics space across the APAC region, recognised for its innovation, customer-first mindset, and strong local presence.

In line with this vision, Ferag continues to prioritise investments in cutting-edge technology and workforce development. The company understands that advancements in AI, machine learning and the use of data lakes are reshaping the industry and is committed to staying ahead of these trends.

“As the landscape of AI and machine learning evolves, we understand the importance of staying ahead by equipping our team with thelatest knowledge and tools,”concludes Michael.

Learn more about Ferag and its services by direct contact via email at info-apac@ferag.com

The positive impact on EBIT from safety

Ferag views safety as a strategic priority that can transform intralogistics operations. By embedding safety into every phase of projects, it helps businesses optimise efficiency, reduce costs, and enhance performance.

This article explores how organisations can take a similar approach, demonstrating how safety drives profitability and enhances operational success.

The positive impact on EBIT from safety

Safety initiatives directly influence the key drivers of EBIT: cost reduction, improved Service Level Agreements (SLAs), and revenue growth. Here’s how:

- Cost savings: Investments in safety reduce incident-related costs such as workplace injuries, downtime, and insurance premiums. These savings directly enhance operational profitability.

- Productivity improvements: A robust safety culture enables employees to work confidently and efficiently, minimising disruptions and delays. This leads to better SLA performance and operational output.

- Compliance and legal protection: Maintaining high safety standards while supporting ESG (Environmental, Social, and Governance) initiatives mitigates legal risks and ensures regulatory compliance. This proactive approach helps organisations avoid penalties and costly lawsuits, protecting both their finances and reputation.

- Workforce retention and attraction: A safe workplace fosters employee loyalty and attracts skilled talent. Reduced turnover ensures knowledge retention, while new talent contributes to enhanced productivity.

- Customer trust and reputation: A strong safety record builds trust with clients, enhancing the organisation’s reputation as a reliable partner. This often results in increased customer retention and market share.

Embedding safety into operations

To realise the benefits of safety, organisations should adopt a systematic approach to embedding safety into their operations. Key strategies include:

- Planning with safety in mind: From the initial stages of project planning, safety considerations should guide the design of processes, systems, and equipment.

- Tailored solutions: Safety systems should be customised to address the unique challenges and risks of each operation.

- Continuous monitoring: Safety is not a one-off initiative. Regular assessments and updates are essential to stay ahead of emerging risks.

- Training and awareness: Comprehensive safety training ensures that employees and stakeholders are aware of their roles in maintaining a safe work environment.

- Leadership commitment: Having dedicated safety leaders ensures that safety remains a priority at all levels of the organisation.

Safety as a strategic investment

While implementing safety measures requires upfront investment, the returns are substantial. Costs associated with documenting procedures, purchasing equipment, and training employees are outweighed by the long-term benefits of reduced incidents, enhanced efficiency, and improved profitability. In addition, organisations with strong safety frameworks often gain a competitive edge in securing new business opportunities, particularly in industries where safety records influence procurement decisions.

Adopting a data-driven approach to risk management, standardisation, and modernising safety systems and training programs can amplify these benefits. This strategy not only reduces costs but also boosts overall productivity, enhances safety awareness, and strengthens customer confidence, positioning organisations for sustained success.

At Ferag, safety is woven into the fabric of every solution delivered. By embedding safety into every aspect of project implementation, Ferag has helped clients achieve smoother operations, mitigate risks, and safeguard their people, assets, and reputation. This approach not only enhances operational performance but also supports long-term business growth.

Organisations that prioritise safety, as Ferag does, can achieve a competitive edge in the market. Safety is more than a responsibility—it’s a strategic advantage that drives efficiency, reduces costs, and improves EBIT. With a strong focus on safety, businesses can achieve operational excellence while fostering trust and loyalty among employees, partners, and clients.

Read the MHD article here

Meeting peak demands with automation

Ferag Managing Director and Head of Region APAC, Karl Friesenbichler, talks about the company’s warehousing solutions.

Ferag is a global company with its APAC head office based in Sydney and its global headquarters in Hinwil/Zurich.

It is a Swiss family-owned group and has been the global market leader in conveying and processing systems in the graphical industry for over 65 years.

Ferag has now shifted focus to Intralogistics and offers end-to-end solutions, from initial consultancy to system integration, project delivery, service and support.

Ferag’s product offerings encompass cutting-edge UCS (WMS/ WCS / WES) software, sortation systems, AMRs and AGVs, as well as service and support to ensure optimal performance.

With a strong emphasis on innovation and technology, Ferag maintains a global presence, represented by 19 sales and service companies, delivering tailored solutions designed to address warehousing demands.

During peak demand periods like Black Friday or promotional events, warehouses often struggle to meet capacity needs, despite the urgent requirement for fast order fulfillment in e-commerce.

As the Managing Director of Ferag APAC, Karl Friesenbichler, explains, this is a key issue – balancing cost efficiency with the need for speedy delivery to satisfy emotionally invested customers.

“The problem with e-commerce is the emotional journey of the buyer,” says Karl. “Once you purchase something, your money is gone, and you feel ownership of the product, even though it’s not yet in your hands. This is the big issue with e-commerce: the emotional aspect.

“As your supplier, I’m in a difficult position because I haven’t yet fulfilled my promise. I must deliver it as soon as possible because of this emotional attachment.”

When considering methods to manage these operations, some of the options are zone routing and automated storage and retrieval systems (AS/RS).

But as Karl explains, the uses for AS/RS systems are situational and a hybrid approach typically offers the best results.

“For large, bulky items, AS/RS can be inefficient, and for fast-moving stock, AS/RS may cause double handling, making it less suitable,” adds Karl.

“AS/RS excels in storage density, fitting many products into a small space, but during peak demand, it may lack the capacity to retrieve stock quickly enough.

“A well-designed warehouse typically combines different systems: fast-moving products are efficiently handled with a conveyor-based system or zone routing, while slower-moving, or less frequent items, can be stored in AS/RS.”

Success stories

Karl says that The Iconic, an online retailer, exemplifies the effective mix of manual and automated picking systems.

“The Iconic is a prime example of mixing manual picking areas with automated picking systems, using multiple different automated systems to meet various product requirements,” he continues.

“Cosmetics, perfumes, or high-value items are stored differently than super fast-moving fashion items, and fragile or dangerous goods require their own handling methods”.

“As an online retailer, The Iconic effectively uses an eclectic mix of systems tailored to their diverse product mix.”

Each system’s validity in the warehouse is crucial, but interconnection is key.

Traditionally, conveyors were used but had issues with space and fire exits. Recently, pouch sorters utilising ceiling space have become popular.

Automated packing integrates seamlessly, eliminating human interaction and easing peak day pressures.

ferag.doWarehouse advanced software further enhances efficiency by predictively moving stock into the pouch system before peak days, reducing peak demand.

These systems can ultimately handle up to 100,000 pouches, processing 30,000 pieces per hour, outperforming conveyors.

“Instead of occupying a large floor area where orders wait for pieces to be gathered from different areas, they utilise pouch sorting,” says Karl.

“This method eliminates restrictions on the number of orders that can be processed simultaneously, allowing operations to scale with demand.”

Demand forecasting

Karl highlights the challenge of forecasting and predicting warehousing demand, noting its propensity for inaccuracies.

Predicting merchandise behaviour proves challenging, but at Ferag, we can analyse product trends and historical data effectively.

“Using doWarehouse’s AI and machine learning, we identify patterns and enhance our forecasts,” says Karl.

“Our data science team supplements this with additional data such as weather patterns, holidays, migration trends, and customer demographics. These factors help predict if a product will sell faster each week, enriching forecasts provided by our customers, our merchandise or sales teams.

“For example, consider soft drinks: sales increase significantly during sunny weekends compared to rainy weather. For fashion items, online sales might spike on rainy winter days when people prefer shopping indoors. Our forecasting models account for these variables to optimise which products are stocked in our systems.”

Ferag have effectively implemented these predictive measures for their clients, namely, Mayoral.

It not only places orders but also collaborates closely with Ferag to continually enhance its systems. It also assesses whether actions were correct or if products need repositioning within an ASRS.

This feedback loop is crucial as it allows ferag.doWarehouse’s machine-learning algorithms to improve over time by learning from successes and failures.

Ferag SkyFall

One of Ferag’s flagship systems is called SkyFall. This is an innovative overhead conveyor system that utilises gravity and the third dimension.

It features a straightforward rail profile with roller bodies, enabling a range of items weighing up to 20 kilograms to be transported from point A to point B.

As Karl explains, the beauty of implementing a system like this is that it causes little disruption to processes.

“When considering how to integrate a significant level of automation into an existing warehouse with minimal disruption, our approach is designed to utilise space efficiently,” he says.

“By constructing automation systems beneath the ceiling, we require minimal floor space. This allows us to integrate new solutions seamlessly with existing infrastructure, minimising disruption.”

Karl says that the Skyfall system has a proven legacy of precision and robust engineering.

“The chain utilised in the SkyFall system has its roots in the graphics industry, initially developed for overhead transportation of newspapers,” he says.

“This gives a vivid image of newspapers gliding across the ceiling, which is essentially what our systems achieve. The technology behind the chain used in these systems has been refined over six decades.”

The technology embedded in these chains has ultimately undergone continuous refinement over six decades, embodying Ferag’s longstanding commitment to engineering excellence.

“There’s this current hype in the market around pouch systems,” says Karl. “It’s intriguing for me to highlight that while SkyFall isn’t a pouch system, the underlying technology that powers it predates this trend by six decades.

“It’s fascinating to witness the reliability, engineering prowess, and the innovative ideas that have shaped our systems through years of learning. These qualities are evident and constitute major feedback from our customers.”

Ferag expands operations in APAC

In a significant milestone of its evolution, Ferag Australia rebrands itself to Ferag APAC, a change aimed at aligning with its expanded presence throughout the Asia-Pacific region.

This change follows a period of extraordinary growth over the past nine months, during which the company expanded from 12 employees in Australia in September 2023 to over 60 employees throughout APAC as of today.

Regional expansion and new offices

Ferag APAC now operates offices in Australia, Malaysia, and India, underscoring its commitment to serving a wider market and enhancing its service capabilities across the region. This strategic expansion supports Ferag APAC’s vision of becoming a leading provider of innovative solutions within the intralogistics sector.

Customer growth and strategic acquisitions

The company’s impressive growth is also evident in its customer base. Following the acquisition of dereOida in September of last year, Ferag APAC has onboarded three iconic brands to its flagship software, ferag.doWarehouse. This strategic acquisition has strengthened Ferag APAC’s market presence and customer portfolio.

Significant increase in female participation

In alignment with its commitment to diversity and inclusion, Ferag APAC has seen a notable increase in female participation within its workforce. Since January, 12 female staff members have joined the team, raising the overall female participation rate from 8 per cent to 22 per cent. Even more remarkable is the rise in female representation in management, which has surged from 0 per cent to 20 per cent. This progress reflects Ferag APAC’s dedication to fostering an inclusive workplace and empowering women in the technology and intralogistics sectors.

Global hub for software development

With its expanded presence, Ferag APAC has become the global hub for the development of its innovative ferag.doWarehouse software. This strategic positioning enhances Ferag APAC’s capability to drive technological advancements and deliver superior software solutions to its global clientele.

Industry context

The broader Australian workplace sees a gender split of 53.4 per cent men and 46.6 per cent women. In contrast, the intralogistics market in Australia has a lower female participation rate, with men making up approximately 75 per cent and women 25 per cent. The Australian software industry reflects a similar gender distribution, with 75 per cent men and 25 per cent women (Australian Bureau of Statistics) (WGEA).

Warehouse Management Systems – How not to get burnt

With the complexity of the market growing due to an influx of solutions and players, businesses embarking on the journey of implementing a warehouse management system (WMS) face exciting yet daunting challenges. According to Ricardo, Sales Director at Ferag, the key to a successful implementation starts with self-knowledge.

“It’s really important for companies to understand their own operations thoroughly. Especially when operations managers are new or unfamiliar with the intricate details of their systems and processes,” Ricardo explains. He emphasises the importance of engaging with every section of the warehouse to grasp what employees experience daily.

Ricardo advocates for a partnership approach rather than a directive one, stressing the importance of choosing a WMS provider who listens and collaborates. “We believe in designing solutions with our clients, not for them. This collaborative approach ensures that the solutions are tailored to the specific needs of the business,” Ricardo says. This strategy not only aligns the system with the company’s existing processes but also enhances the overall functionality and integration of the WMS.

Addressing the automation dilemma, Ricardo suggests a cautious approach. “The best option often is not to jump straight into automation but to first understand and streamline your current processes,” he advises. This initial step allows for a more informed decision on whether automation is necessary or if manual processes simply need refining. Ricardo highlights the importance of identifying the most resource-intensive aspects of operations, such as labour and space, which are typically the most costly and impactful areas to address.

Furthermore, Ricardo points out the significance of data accuracy in the configuration of a WMS. “Data is the most critical part of warehouse design. If the data is incorrect, the whole solution will be flawed, regardless of how advanced the system is,” he says. He encourages businesses to ensure their WMS provider is not only taking in data but also thoroughly analysing it to understand the full scope of operations from receiving to shipping.

Ferag employs data scientists to enrich and verify data, ensuring that solutions are based on accurate and comprehensive information. “We don’t just accept the data we’re given; we delve into it, challenge assumptions, and enhance it to develop the most effective solutions,” Ricardo shares. This meticulous attention to data serves as a foundation for any WMS implementation, aiming to optimise efficiency and accuracy across all warehouse operations.

When it comes to implementation methodologies, Ricardo underlines the importance of a proven, flexible approach. “We adhere to industry-standard methodologies that allow for agility and quick adaptation, which is crucial for integrating new automation technologies as business needs evolve,” he explains. This flexibility is vital for maintaining cost-effectiveness and ensuring that the WMS can adapt to future changes within the company.

Ricardo also addresses the broader goals businesses typically aim to achieve through a WMS. “The primary aims are to enhance labour efficiency, maximise space utilisation, and improve overall operational throughput,” he states. By focusing on these areas, companies can not only improve their immediate operations but also lay a solid foundation for future growth and efficiency.

In terms of dealing with potential issues during the WMS implementation, Ricardo suggests that businesses should look for a partner who is prepared to adapt the solution to their needs rather than forcing the company to conform to the software. “It’s about finding a partner who is willing to mould their solutions around your processes, ensuring the WMS complements your operations rather than complicating them,” he remarks.

Lastly, Ricardo touches on the critical nature of choosing whether to automate certain operations or to refine manual processes. “Investing in the right areas at the right time is crucial. You may discover that enhancing your current operations is more beneficial than full automation,” he advises. This strategic approach allows businesses to optimise their investments, ensuring that any technological advancements, like WMS, genuinely benefit the operational dynamics and contribute to long-term success.

As businesses continue to navigate the complex landscape of warehouse management systems, the insights provided by Ricardo underscore the importance of a thoughtful, data-driven approach in selecting a WMS provider. By focusing on collaboration, data integrity, and strategic investment in technology, companies can enhance their operational efficiency and pave the way for sustained growth

Read the MHD article here

Why are some of Australia’s largest iconic brands jumping on board with the new kid on the block?

In the last few months, some of Australia’s largest and most prestigious brands have implemented ferag.doWarehouse (previously from dereOida). This roll-out includes major department stores, online retailers, third-party logistics providers (3PLs), amongst others. Most of these industry leaders are either in the process of going live, or already live with doWarehouse!

So, what sets this upstart Warehouse Management System (WMS) apart? Like every other WMS, it increases warehouse operations’ efficiency, boosts productivity, reduces order times, enhances stock accuracy, and supports cycle counting.

However, doWarehouse’s innovative approach distinguishes it from competitors. It is much more than just a WMS. It is a Unified Control System (UCS), which means it is a WMS, Warehouse Control System (WCS), Warehouse Execution System (WES) and/ or anything in between. Interfacing from your Enterprise Resource Planning (ERP) software all the way down to Program Logic Controller (PLC) level. It is fully and truly agnostic, offering best-in-class abstraction and optimisation, allowing for highly flexible and easy integration with equipment. In layman’s terms, doWarehouse not only manages your entire warehouse—it can also seamlessly integrate with your robots, warehouse hardware, and machinery, resulting in significant time and cost savings. You are no longer locked into outdated or unsuitable hardware, and you can select equipment that best suits your processes with the confidence that doWarehouse will manage them effortlessly.

Unlike other WMS providers, doWarehouse doesn’t require you to change your processes to fit the software. Most systems force you to mould your well-honed processes to their configuration—not so with doWarehouse! It also provides the flexibility to adapt new processes and functionalities as business needs evolve, such as shifting from retail to an online platform or integrating automated processes.

Its seamless integration and analytics enable quick and effortless setup and provides ongoing control and visibility of not only the different warehouse tasks, but also of their costs via meaningful reports and dashboards.

doWarehouse has been developed from the ground up utilising a state-of-the-art technology stack. This provides independence from the server operating system, it also offers scalability and excellent utilisation of server resources. In addition, dowarehouse’s modern architecture facilitates significantly quicker and cheaper modification and customisation.

In summary, doWarehouse UCS enables you to choose the equipment that best meets your warehouse requirements as well as stay up to date with the latest technology, without having to compromise on functionality.

doWarehouse was previously a part of dereOida. In September 2023, Ferag acquired dereOida, bringing doWarehouse and the Australian dereOida team into its fold.

Read the MHD article here:

Geek+ and Ferag announce partnership

Geekplus, the mobile robot and smart logistics solutions company with Ferag APAC have announced a partnership, which will empower Ferag APAC to supply, install, and service Geekplus equipment.

Ferag notes this partnership will help it establish itself as a comprehensive solution provider for the Asia-Pacific region.

“I am delighted to partner with Geekplus for the sales and implementation of their robotics,” says Managing Director for the Asia Pacific at Ferag, Karl Friesenbichler.

“Many of our clients, including Myer – who has notably installed three Geekplus models, the Tote-to-Person, Shelf-to-Person and sorting solutions – are already reaping the benefits of Geekplus robots.”

Known for its pioneering solutions in order fulfilment, Geekplus caters to more than a 1000 international clients. Founded in 2015, the company has broadened its operations globally – now employing a workforce exceeding 1500.

It holds a strong market presence in the United States, Germany, the United Kingdom, Japan, South Korea, Mainland China, the Hong Kong SAR, and Singapore.

Ferag as the ultimate one-stop shop, consistently meets its clients’ exacting requirements with solutions that are both timely and within budget.

“Our strategic partnership with Ferag has been instrumental in supporting our market growth in the Asia-Pacific region,” says Head of International Business at Geekplus, Lit Fung.

“By leveraging their experience and adhering to the highest quality and service standards in system integration, we are ensuring efficient operations in our clients’ distribution centres. Looking ahead, we are excited about the prospects of more projects going live as a result of our collaboration with Ferag.”

This strategic alliance unites Geekplus’s cutting-edge suite of Goods-to-Person mobile robotic solutions with Ferag’s systems integration expertise and advanced warehouse software to offer clients across the Asia-Pacific region a fully integrated warehouse system tailored to their stringent specifications.

Ferag AG joins forces with dereOida

Ferag AG and dereOida have announced their merger, combining their expertise and innovations to create a comprehensive, single solution for all intralogistics requirements.

Ferag AG, a renowned family-owned Swiss company with more than 65 years of experience as a global market leader in material flow systems, and dereOida, an Australian pioneer in warehouse automation software with its revolutionary doWarehouse system, are uniting their strengths to offer an unparalleled intralogistics solution to businesses across various industries.

“We are thrilled to announce the merger with dereOida, a strategic move that marks an exciting chapter in the growth of our two companies,” says Tommaso Ramundo, CEO Ferag AG.

“This partnership brings together two industry innovators with a shared commitment to excellence and quality. By combining the strengths of Ferag and dereOida, we are able to offer an even more comprehensive range of solutions to our valued customers.”

dereOida’s flagship product, doWarehouse, presents a holistic single view across the warehouse. With the freedom to select any automated system, customers can seamlessly integrate their chosen hardware into doWarehouse, all while benefitting from dereOida’s outstanding support services.

The merger of these two industry innovators presents a transformative offering for businesses seeking to optimise their warehouse operations. By combining dereOida’s state-of-the-art software solutions with Ferag’s unparalleled expertise in material flow systems and design, customers can expect an end-to-end solution that addresses every aspect of intralogistics with unprecedented quality, reliability, and support.

“The synergy between our teams and the complementarity of our offerings create a powerful force this will undoubtedly shape the future of our industry,” says Karl Friesenbichler, CEO dereOida.

“The combined expertise and resources of Ferag and dereOida will allow us to explore new horizons and drive innovation in every aspect. We are confident that this merger will lead to remarkable results and increase the value we provide to our customers, partners and stakeholders.”

Key benefits of the acquisition:

Comprehensive Intralogistics Solutions: Customers now have access to a complete suite of intralogistics solutions that cover the entire spectrum of warehouse automation and management.

Synergy of Expertise: The merger brings together Ferag’s decades of experience in equipment intralogistics with dereOida’s cutting-edge automation software, resulting in a holistic and advanced hardware and software intralogistics solution.

Optimised Productivity: Businesses can leverage the power of doWarehouse’s real-time insights and analytics to drive continuous improvements and optimise their operations.

Simplified Support: dereOida’s single point of contact for hardware and software support ensures seamless assistance and quick issue resolution for enhanced customer satisfaction.

Read the full article here